Anleitung: Kantenfinder / Tastplatte für estlcam benutzen

Durch diese Tastplatte lässt sich einfach und präzise die genaue Lage der Kanten, des Nullpunkts und die Ausrichtung des Werkstücks erfassen.

Funktionsweise

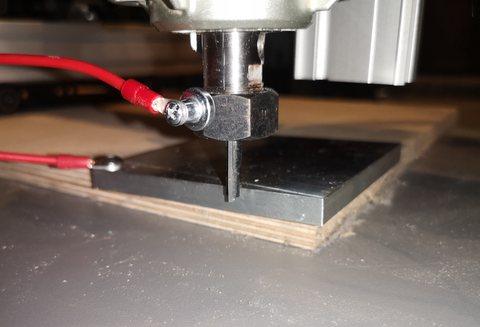

Die Tastplatte wird an einen Eingang der Steuerung angeschlossen. Gleichzeitig wird der Fräser, welcher in der Spindel eingespannt wird, mit GND verbunden.

Die Tastplatte wird auf die die Ecke des Werkstücks aufgelegt. Nun lässt man die Fräse Schritt für Schritt anfahren. Nach jedem Schritt überprüft die CNC-Steuerung automatisch, ob der Steuerkreis geschlossen wurde und damit der Fräser an der Kante der Tastplatte ansteht. Dies wird aus verschiedenen Winkeln wiederholt. Über eine Dreipunktmessung kann so die Lage und Ausrichtung des Werkstücks berechnet werden und über eine vierte Messung die Höhe erfasst werden.

Konfiguration

Zunächst müsst ihr prüfen, ob euer Fräser geerdet ist. Sollte er nicht geerdet sein, könnt ihr eine extra Kabel ziehen und den Fräser mithilfe einer Krokodilklemme oder eines Magneten erden. Auch die Tastplatte muss mit einem Steuereingang verbunden werden. Aufgrund der Vielzahl an möglichen Steuerungen müssen wir euch hier an eueren Steuerungsanbieter verweisen.

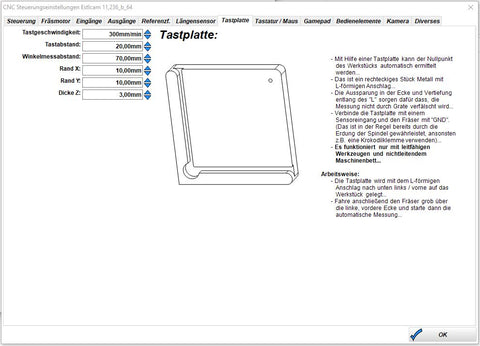

In Estlcam wählt ihr in der Steuerleiste > Einstellungen > CNC Steuerung aus und wählt dort den Tab "Tastplatte".

Entsprechend unserem Screenshot aus Estlcam von Christian Knüll wählt konfiguriert ihr Rand X: 10mm, Rand Y: 10mm und Dicke Z: 3mm:

Screenshot aus Estlcam

Nutzung

Wenn ihr die Tastplatte erfolgreich konfiguriert habt, fahrt ihr mit dem Fräser über die linke obere Ecke der auf der Werkstück aufgelegten Tastplatte und wählt dann unter CNC Steuerung (F2) den Punkt antasten aus.